Product

Better with customers

A company that makes

the future

GYG Elevator

Rope Gripper is responsible

for the safety of our customers.

Rope Gripper ™ is an over speed protection device that protects passengers from the risk of injury due to failure of the brake control system of the elevator, breakdown of the brake, and failure of the component that determines the car speed in the ascending or descending direction. If the elevator car door is open due to slipping or if it exceeds the rated speed, it will stop the car safely by catching the main rope of the elevator when sudden rise or fall.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

When ordering a Rope Gripper, please describe the following information in detail.

Max. Out to Out of Cables, number of main rope and rope diameter, roping arrangement (such as 1: 1 or 2: 1), Rated Speed, Car Rated Load, Car & Counterweight Mass, Total System Load (Car, Car Load, Counterweight, Hoist and Compensation Rope Mass)

Main Parts Name

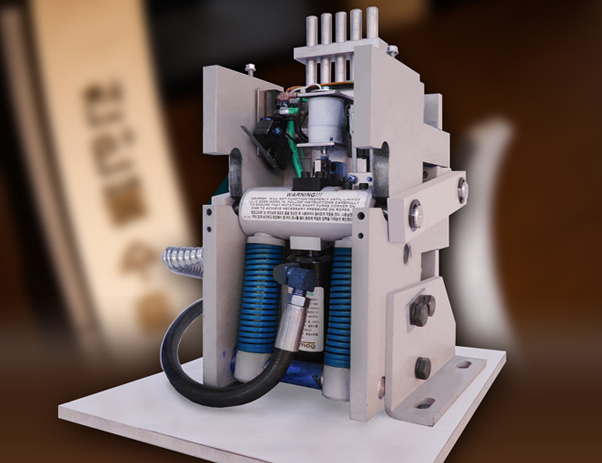

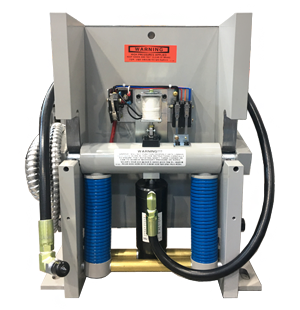

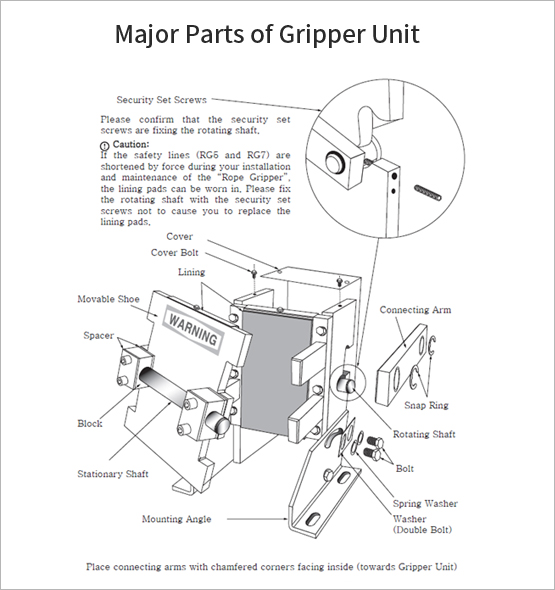

Gripper Unit

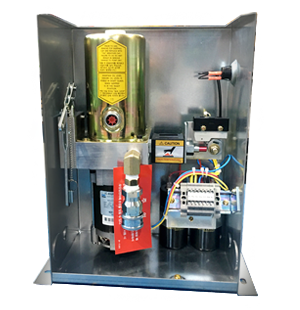

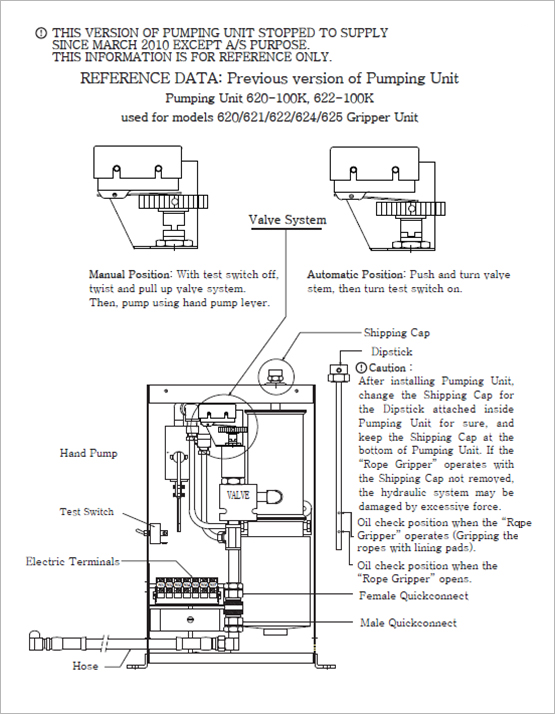

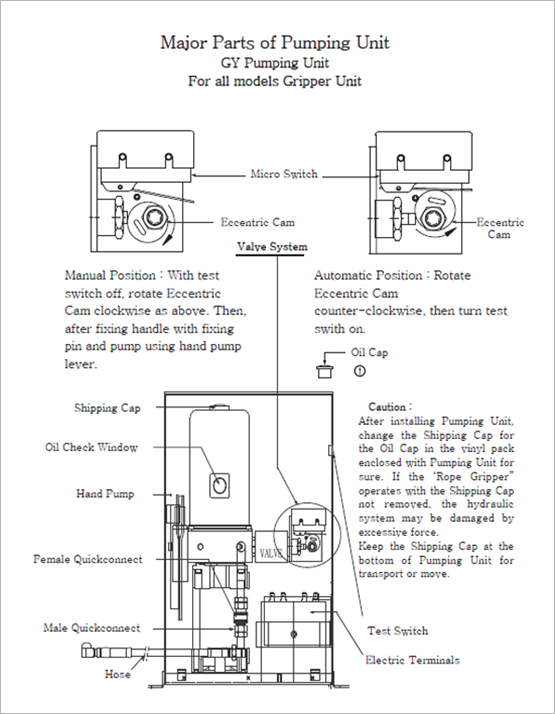

Pumping Unit

01

Using a spring moving along the fixed cam

It has the mechanical advantage of using a spring that moves along the fixed cam, so it can grab the main rope strongly but smoothly so that excessive pressure or damage can not be applied to the main rope of the elevator without modifying the machine or hoisting machine sheave or other devices.

02

It is possible to prevent accidents when the slipping phenomenon of the traction machine occurs.

When the slipping phenomenon of the traction machine occurs, the accident can be prevented. This cam action is designed to compensate for lining wear and spring drooping so that constant pressure is applied to the elevator rope, even if the spring force is reduced to less than half the original.

Obtained CSA quality certification

Successful localization from Hollister-Whitney with quality certified products from CSA and supply at practical price

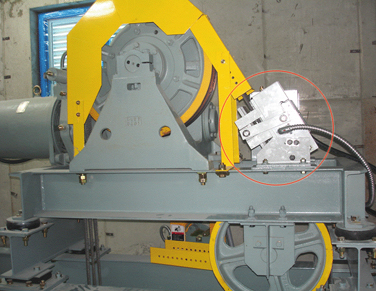

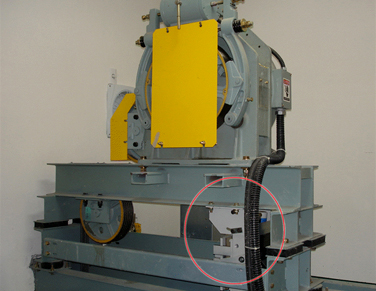

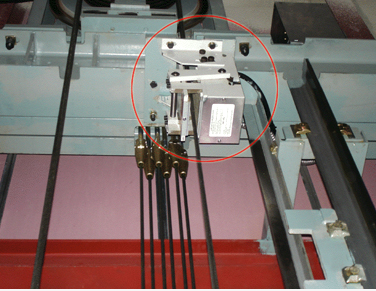

Field installed pictures

Geared

Gearless

MRL